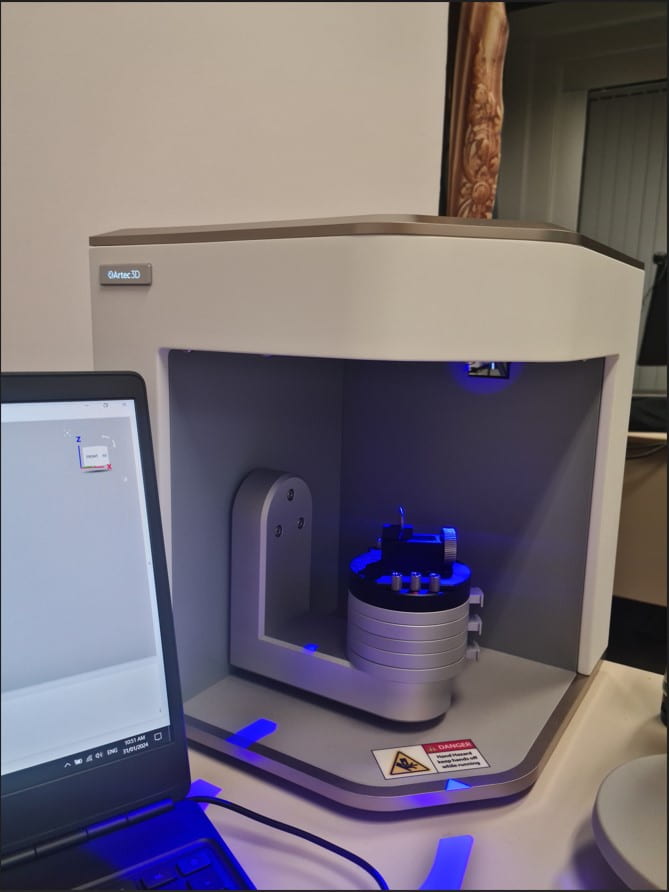

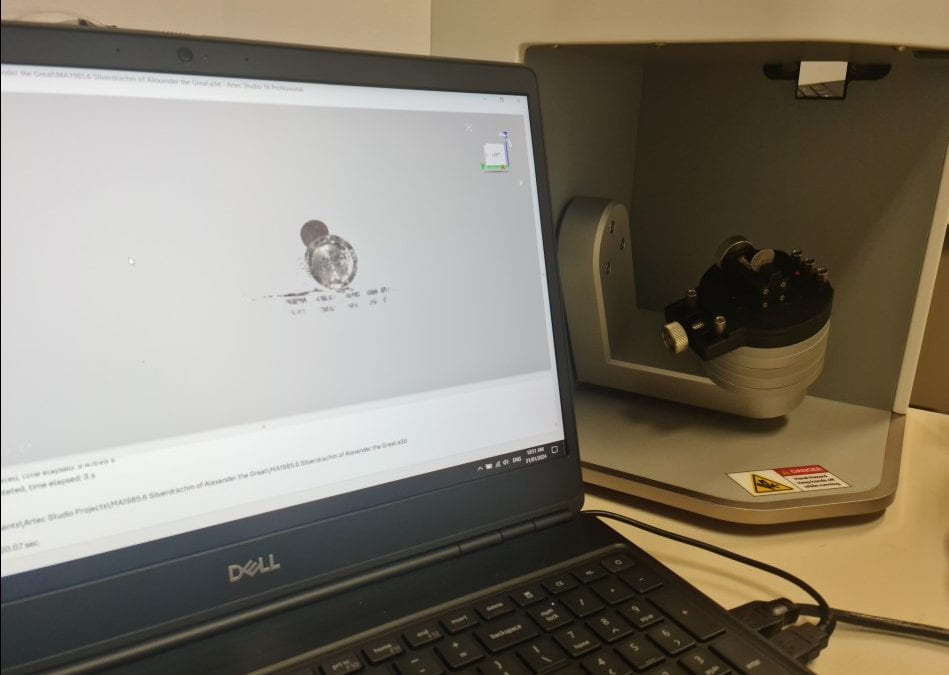

UNE has levelled up its digital capabilities with the acquisition of an Artec Micro3D Scanner for micron-accurate reproductions of small objects, such as ancient coins.

The scanner was purchased by UNE’s Museum of Antiquities (UNEMA), but will be able to be used for teaching, research and community engagement across a range of UNE programs.

“Being able to scan really small artefacts that, until now, has been beyond the ability of a standard 3D scanner or photogrammetry rig, opens up a whole new range of digital and physical three-dimensional teaching resources to staff and students,” UNEMA’s collections manager, Dr Bronwyn Hopwood, says.

She sees the benefits stretching across the arts and humanities to science and medicine.

“You can scan items that may otherwise be too small and delicate for continuous handling to digitally inspect them more closely, as well as reproduce them using 3D printing. This could be used on a sequin from a costume or element of a musical instrument, a tiny inscription, a stone tool or insect. You can scan objects and equipment and even medical devices to then 3D print. Its uses are only limited by time and imagination.

“Digitising objects improves UNE’s capacity for teaching and research, as the scanned objects from a cultural or scientific collection can be fully accessed outside of opening hours, and from remote locations.”

Dr Hopwood also says that the scanning skills students and researchers learn can be taken into a range of careers.

“The equipment helps our students become job ready at the cutting-edge of the digital industry.

“If we train a student to scan an ancient pot from the museum, that student can take those scanning skills into the automotive industry where digital scanning and editing is used to design and manufacture car parts; or the dental industry where 3D scanning and printing is being used to provide custom-fit caps, dentures, and sports mouth-guards. Same skills, multiple applications.”

3D scanning technician Jackson Shoobert, from the UNE Learning Media Team, says these are skills anyone can acquire with a short amount of training, and scanned models can usually be produced in 30 minutes to one hour.

While 3D printing has become more commonplace over the last decade, scanners like the Artec Micro3D Scanner are not a device that you usually expect to see.

“UNEMA was able to purchase the Micro3D as part of a successful grant application supported by the Faculty or Humanities, Arts, Social Sciences, and Education,” Dr Hopwood says.

“The Micro3D provides superior 3D scanning for small and intricate objects at the cutting-edge of digital technology, which is a focus in the Faculty of HASSE.”

The Artec Micro3D scanner is currently housed with the Learning Media Team in the ITD building while UNEMA’s refurbishment is underway. Contact Jackson Shoobert for further information.

Recent Comments