I used to temper the clay and wheel it to the table, and as he moulded the bricks he placed them on the board of my barrow, and I wheeled them to the drying ground. These bricks were used for building a long row of cells for separate treatment. (1)

If you visit pretty much any convict site in Tasmania you will undoubtedly find buildings made of brick – or a scatter of bricks where such a structure used to be. As a building medium, it was even more ubiquitous than dolerite and sandstone, being relatively easy to produce in the quantities needed. Labour returns for convict stations often detail that gangs of men were engaged in digging clay and making bricks, with another smaller team employed in bricklaying. As with most convict occupations, the production and use of bricks encompassed a full range of skills. This meant that the authorities could deploy prisoners with different types of skill and requiring different levels of censure.

On the Tasman and Forestier’s Peninsula most of the nine major convict stations were located near clay sources. As an important resource, clay would have been identified either at the time of the initial survey, or very soon after the place had been established. However, we do know that Port Arthur was not settled with clay in mind, with clay pits not opened until late 1831 (a year after settlement). Until that time bricks were imported to the station, likely used to build the chimney elements of the few buildings then established.

Large stations like Port Arthur and Coal Mines often had more than one clay pit which had been worked at separate points during the station’s operation. This was either due to a resource becoming exhausted, or a better source being found. At Port Arthur the first clay source was located one mile south east of the station, at a place subsequently known as Brick Point. The then Commandant John Gibbons described it as having:

Clay of a most excellent description for brick making…(2)

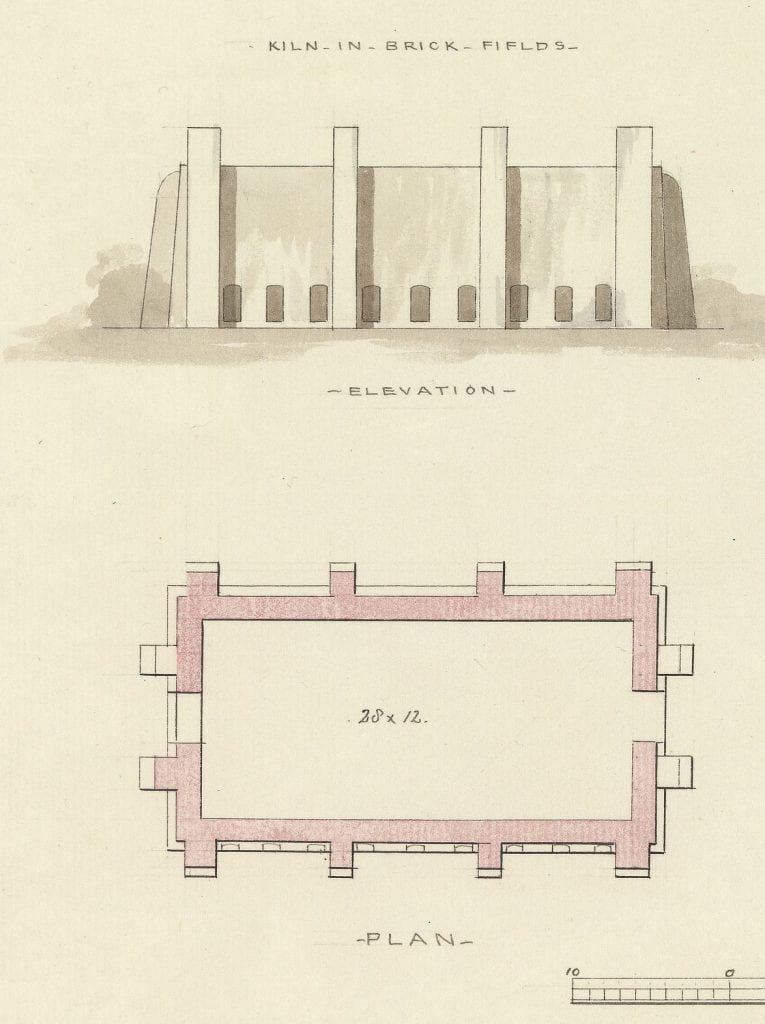

By 1836 a large drying shed and Scotch kiln were established at Brick Point, where 6-10 men worked as brickmakers (and probably twice that dug the clay and gathered the timber for the kiln). The kiln was likely able to produce upward of 30,000 bricks per firing, with anywhere between 1-3 firings per month. Such an output would have gone a long way toward making the station self-sufficient in this building material. By way of an example, a small detached stable was recorded as requiring 15,000 bricks. (3)

Plan and elevation of the Brick Point brick kiln (Henry Laing, ‘Kiln in Brick Fields’, ca.1836, CON87/1/53, Tasmanian Archives)

Around 1842 the brickmaking operations shifted to a new area. Situated just north of the station, at a place that unsurprisingly became known as Brickfield Hill, this became the site of brickmaking operations until the close of settlement. Like Brick Point, a drying shed and kiln was situated at the site, where brickmakers, clay and earth diggers, and timber-getters worked. Production returns in 1846 indicate that the works were capable of producing over 900,000 bricks per year. The brickmakers continued working here until the end of the convict period, the production gradually dwindling as there were fewer and fewer men capable of carrying out the labour. The last return we have in 1873 indicates that only 15,000 bricks were produced in that year. After 1877 the site continued to be used, with potters James Price (1886-1912) and Tom Mason (1890s) setting up shop. The beehive kiln that you now see on Brickfield Hill is from that era.

As archaeologists we deal with the outputs of the brickmakers on a daily basis. All the bricks we find from the convict period are handmade, having been shaped in a mould, air-dried in a shed and then fired in a kiln. As such, we find many bricks with thumb prints (from pressing the still-plastic clay out of the mould), hack marks (imprints from where the semi-dried brick had been stacked against other bricks) and, sometimes, animal paw prints (from cheeky critters wandering over bricks in the drying shed). We can tell 1830s bricks from those made later, the early bricks often being poorly-mixed and of a much lighter orange colour. Later bricks are often a rich orange or reddish orange.

LiDAR-derived visualisation of the Brickfield Hill clay pits (Landscapes of Production and Punishment, 2017-20)

We can even use technological whizz-bangery to investigate the processes of clay extraction and brickmaking. As we did with the sandstone quarry, we have used LiDAR to estimate the volume of clay removed from the post-1842 clay pits at Port Arthur. This indicated that the Brickfield Hill clay pits produced enough clay to make 2.9 — 3.2 million bricks. Task work rates tell us that the minimum rate of brick production per man was 125 bricks per day, meaning that this volume of bricks would have required over 20,000 person days of work working for 65 years. Like the dolerite and sandstone that makes up Port Arthur, it is clear that even the humble brick represents yet another aspect of the penal station’s unrelenting labour machine.

If you want to know more about brickmaking, we are about to release a special edition of Journal of Australian Colonial History that includes a paper by Julie Sebanc-Butler, Martin Gibbs and myself examining the history and archaeology brickmaking on the Tasman Peninsula. Stay tuned!

- Julia Clark (ed.), The Career of William Thompson, p. 98.

- Gibbons, Commandant, to Burnett, Colonial Secretary, 4 December 1832, CSO1/630/14256, Tasmanian Archives.

- Acting Foreman of Works to Victor, Commanding Royal Engineer, 25 January 1839, CS05/174/4142, Tasmanian Archives.