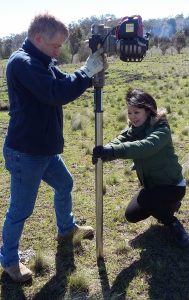

As part of the activities on UNE1601 we’ve been coring three times a season to a depth of 1 m under various cotton rotaitons.

Now this in itself is not earth shattering news, but I’ve just been and picked up coring tube Mark V, yes five!

The newest cromoly core is hopefully stronger than it’s two stainless steel predecessors. Hopefull the braised tip will not meet the same fate as two of its predecessors, which now rest somewhere under a meter of vertosol and hopefully the stronger metal will not deform under the new singel piece solid dolly. Oh yes, we’ve broken at least two dollies over the two seasons of use so far. We’ve also broken and melted several sample recovery tubes as well, so whilst in principle banging a metal core into soil is easy, we just wanted to point out that it is, however, rarely without issues and challenges. So how do we cope? We always have a back up plan, as many spares as we can travel and a high degree of ingenuity. Should also point out that we have a workshop who greatly support our endevours. Thanks guys. Hopefully we’ll not be back in a couple of months with more repairs and modifications.

Recent Comments